As technology continues to evolve, the future of electronics manufacturing is becoming increasingly complex. Advances in engineering and materials science have enabled manufacturers to create sophisticated electronic devices with unprecedented capabilities.

From wearable medical monitors to space-based satellite systems, these cutting-edge products are setting new standards for performance and efficiency. But what does this mean for the industry as a whole? In this article, we explore emerging technologies and trends related to electronics manufacturing that will shape the sector’s future.

We look at how manufacturers can leverage advances in automation, miniaturization, and data analytics to design and produce more efficient products while maintaining long-term sustainability goals. Additionally, we consider potential challenges posed by rising costs, regulatory changes, security risks, supply chain disruptions, and other factors that could affect industry growth prospects over time.

Automation and Robotics in Electronics Manufacturing

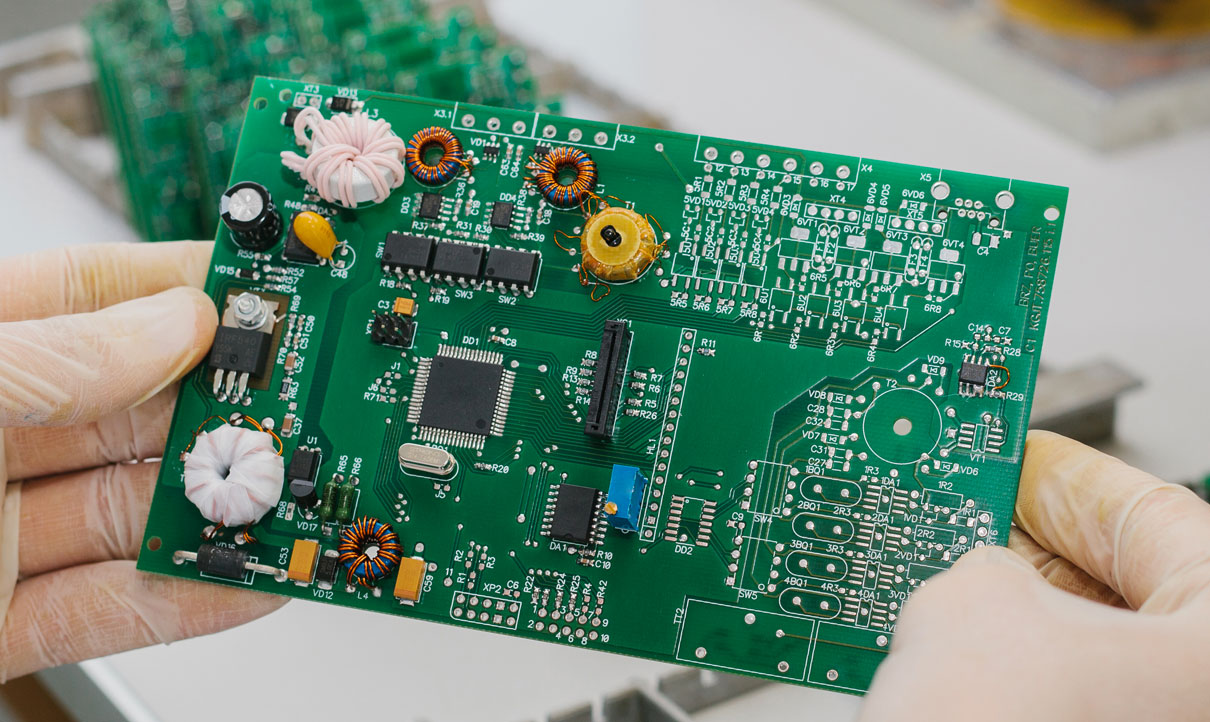

Automation and robotics are revolutionizing electronics manufacturing, including PCB assembly. By integrating robots into the production lines, companies are able to increase their efficiency and output while reducing costs associated with labor and downtime. Automated systems can also reduce human error in certain processes, ensuring that products meet all safety standards before leaving the factory floor.

Additionally, automation eliminates tedious tasks from workers’ daily routines, allowing them to focus on more complex activities and improving job satisfaction. Robotics is playing a key role in modern electronics manufacturing, including PCB assembly, by streamlining processes such as assembly, testing, and packaging, making it easier for manufacturers to produce higher quality products at lower costs than ever before.

With advances in technology continuing to drive down the price of these machines, they look set to become increasingly commonplace within this industry over the coming years – transforming how we think about electronics manufacturing forever.

Additive Manufacturing for Electronics Production

Additive Manufacturing for Electronics Production is an emerging technology that offers a range of benefits for electronics manufacturing. This method uses 3D printing techniques to create complex and intricate parts with precision and accuracy. It eliminates the need for manual labor, meaning fewer errors are made during production.

Additive Manufacturing also reduces waste as it only uses the materials necessary to produce each component. Furthermore, this process can be used in combination with traditional methods, allowing manufacturers greater control over their production processes. As additive manufacturing becomes more widely adopted in electronics production, companies will have access to faster and cheaper solutions than ever before – opening up new possibilities for innovation in the sector.

Integration of Internet-of-Things Technology in Electronics Manufacturing

The integration of Internet-of-Things (IoT) technology in electronics manufacturing is a major part of the future. IoT has revolutionized how manufacturers can monitor, collect and analyze data from their processes, leading to increased efficiency and improved outcomes.

This technology allows machines to communicate with each other and process information quickly and accurately, making it easier for manufacturers to optimize production lines. It also helps reduce wastage by providing real-time analysis on inventory levels, helping ensure that all parts are used efficiently. Additionally, IoT can help enhance safety measures within factories by allowing companies to monitor hazardous conditions or areas that pose a risk of injury or death. With the advances in this technology, electronics manufacturers will be able to stay ahead of competitors while improving overall productivity levels.

Artificial Intelligence in the Design and Manufacture of Electronic Products

As the world of electronics manufacturing continues to evolve, Artificial Intelligence (AI) has become an ever-increasingly important factor in the design and manufacture of electronic products. AI technology can provide a range of benefits to companies involved in this industry, including faster product development times, improved accuracy and reliability of designs, and enhanced customer service capabilities. AI can also be used to automate certain production processes that would otherwise need manual intervention.

By employing advanced algorithms and analytics tools, manufacturers are able to quickly identify defects or errors during production runs that may have been otherwise overlooked by human operators. Additionally, AI-driven automation allows for more efficient use of resources such as materials and labor costs over time.

Furthermore, when it comes to complex tasks like designing intricate components or circuit boards for example, AI is capable of reducing the amount of trial and error needed before reaching a satisfactory result – making it easier for companies to develop innovative solutions at their desired pace. In conclusion, with its numerous advantages across all stages from design through production testing & evaluation – Artificial Intelligence is set up to play an integral role in the future success story of electronics manufacturing around the globe.

Optimization of Supply Chains for Improved Efficiency in Electronics Manufacturing

As electronics manufacturing continues to grow in sophistication, the need for efficient supply chains becomes increasingly important. Companies must find ways to optimize their supply chain systems and processes to better manage costs and reduce waste. This can be done by leveraging emerging technologies like big data analytics, artificial intelligence (AI), machine learning, blockchain technology, and IoT sensors.

Big data analytics can provide insights into customer demand patterns which will enable companies to make timely inventory decisions. AI-powered predictive analytics can help identify potential issues in the supply chain before they occur while also providing recommendations on how best to resolve them. Machine learning algorithms are being used more frequently as well, helping manufacturers understand past purchasing trends so they can make smarter decisions in the future.

Blockchain is another tool that has become critical for improving efficiency within supply chains, allowing companies to securely transfer goods between vendors without fear of fraud or mismanagement of funds. Finally, IoT sensors allow companies to monitor shipments along every step of a given route and alert stakeholders if there is any delay or disruption in service – thus ensuring smooth operations at all times. By utilizing these tools effectively, organizations have a greater chance at optimizing their supply chains for improved efficiency in electronics manufacturing now and into the future