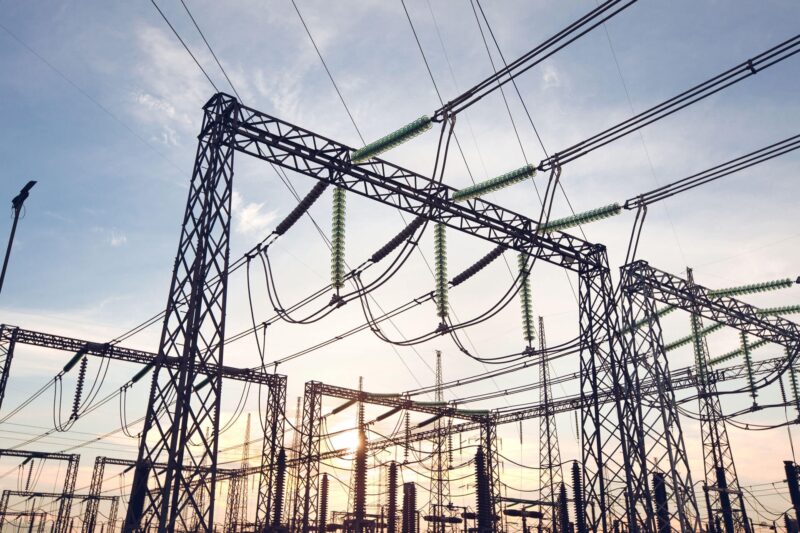

Substation design and engineering services are critical to delivering safe, reliable power projects that meet network standards and support long term operational performance. Whether the project involves new substations, upgrades, renewable integration, or capacity expansion, a well engineered substation improves power quality, strengthens protection systems, and reduces the risk of outages. Successful delivery depends on coordinated electrical, civil, and control design that aligns with utility requirements and project timelines.

Core substation design scope and key deliverables

In the first paragraph after this heading, Power Grid Engineering’s exemplary electrical grids reflect the importance of disciplined design practices that balance safety, constructability, and future expansion requirements.

Substation design typically covers primary plant layout, equipment selection, earthing and bonding, insulation coordination, and protection and control systems. Key deliverables include single line diagrams, general arrangement drawings, equipment specifications, cable schedules, protection schemes, and commissioning plans.

Civil works also form a major part of design, including foundations, site grading, drainage, oil containment, fencing, and access roads. Good design accounts for clearances, maintainability, and safe work zones so operational teams can inspect and service equipment efficiently throughout its lifecycle.

Protection, control, and safety in modern power projects

Protection and control design ensures faults are detected quickly and isolated to minimise impact on the network. This includes relay coordination, CT and VT selection, breaker failure schemes, and communications for SCADA and remote operation.

Modern substations increasingly integrate digital systems such as IEC 61850, improving data availability and reducing wiring complexity, but also increasing the need for cybersecurity and configuration discipline.

Safety considerations include arc flash risk management, step and touch potential calculations for earthing systems, and clear separation of high voltage zones. Designers also plan for compliance with relevant standards and utility rules, including clearances, signage, and access control. A strong commissioning and testing plan helps verify that protection functions operate correctly before energisation and provides traceable records for handover.

Project execution, constructability, and future readiness

Substation projects often involve tight outages, multiple stakeholders, and long lead time equipment. Engineering services can support procurement, technical evaluations, and construction staging plans that reduce schedule risk. Constructability reviews help ensure equipment can be installed safely with available lifting access and that cable routes, trenches, and conduits are coordinated with civil works to avoid clashes and rework.

Future readiness is also essential. Many substations need space and design provisions for additional feeders, transformers, or reactive power equipment. Designing with expansion in mind reduces future cost and minimises disruption when network demand grows. Documentation, as built records, and clear operational procedures also help asset owners maintain reliability over the long term.

Conclusion

Substation design and engineering services provide the foundation for safe, reliable power projects by coordinating primary plant, protection and control, and civil works into a buildable and maintainable solution. With strong standards alignment, disciplined safety design, and future focused planning, substations can support dependable network performance for decades.