Many products we use daily rely on very advanced materials that make possible miniaturization, improved performance and increased functionality. These materials incorporate innovations at the molecular or nano-scale level to achieve new properties. They include ultra strong plastics, flexible glass, shape-memory alloys, high-density batteries, durable lightweight composites and more.

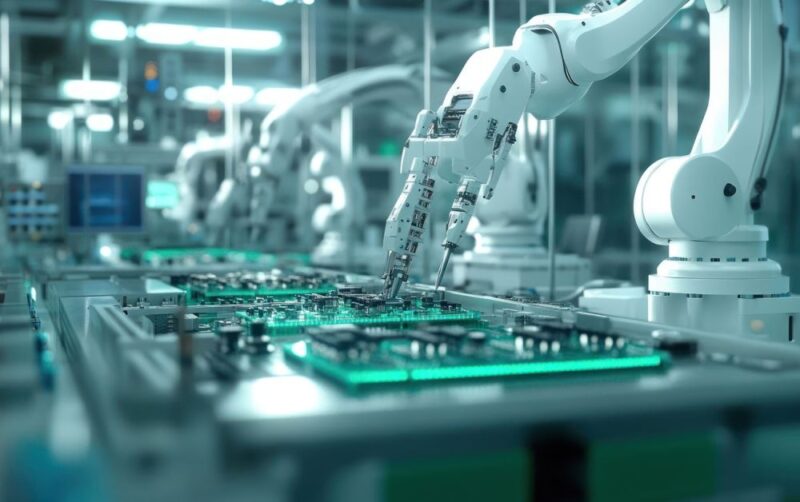

Precision manufacturing methods produce these materials for applications in aerospace, computing, healthcare, transportation, energy and beyond. The specially engineered materials offer capabilities matching or exceeding conventional offerings at typically higher costs, though costs diminish given time and scaling.

Key Properties of High-Tech Materials

Engineered for extreme demands, high-tech materials outperform traditional materials in several ways:

- Strength & Durability – Materials like graphene fiber match steel’s strength at a fraction of the weight while resisting wear and corrosion. Carbon nanotubes are stronger than steel but lightweight.

- Light Weight – Replacing metals with lightweight polymer composites cuts fuel consumption in vehicles and aircraft. Magnesium or advanced aluminum alloys also provide ultralight solutions.

- Electrical Conductivity – Materials called perovskites enable efficient solar panels. Conductive plastics simplify production of sensors and circuits. Printable electronics gain from nano inks.

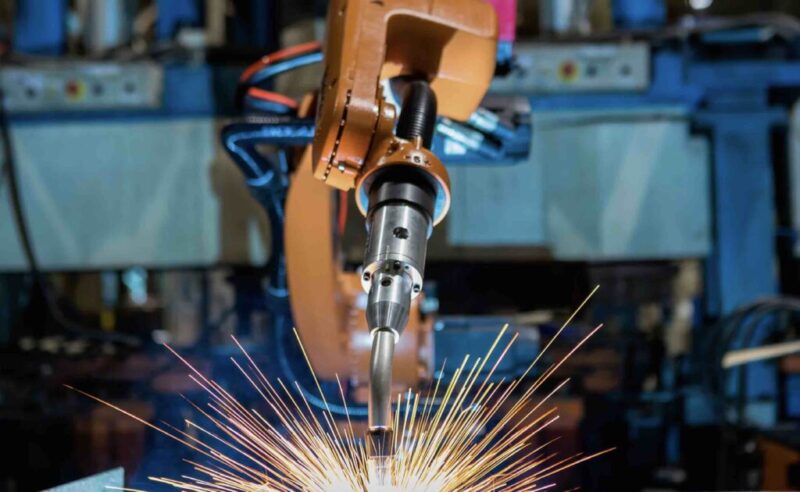

- Heat/Chemical Resistance – Specialty ceramics withstand molten metal and extreme temperatures in foundries or nuclear plants. Other materials work in highly acidic chemical processes that rapidly degrade steel.

Rising Market Pull Across Industries

Many factors drive the surging popularity of advanced and high-tech materials:

- Fuel Efficiency – New lighter weight metal alloys and polymer composites improve transport efficiency and range in the aerospace, marine, and automotive sectors. Electric vehicles also benefit.

- Electronics Innovation – Faster, smaller gadgets and batteries gain from nanomaterials research producing quantum dots, nano-sensors, and future transistors made from wonder materials like graphene.

- Extreme Environment Tolerance – Industries like oil/gas, mining, chemical processing, aviation and space technology require specialized materials that endure under punishing mechanical loads, caustic chemicals, temperature swings and radiation exposure.

- Sustainability – Renewable energy, green construction and packaging firms increasingly seek eco-friendly high-tech materials with lower embedded energy costs, reduced waste, recyclability and other green advantages. Partnering Between Manufacturers and Material Suppliers

Successfully applying high-tech materials involves collaboration between end product makers and specialty chemical/material suppliers. For instance, a specialty polymers manufacturer like Trecora might work with a sporting goods company to develop new custom composites for athletic shoes and protective sports gear.

Combining the footwear firm’s market insights with the material supplier’s polymer expertise results in high-performance products with expanded consumer appeal. Similar joint efforts across industries will unleash further high-tech material innovation.

Challenges With High-Tech Materials

Maximizing the promise of high-tech materials demands overcoming difficulties, including:

- New Manufacturing Methods – Harnessing unique properties requires adapting processing techniques and supply chain capabilities from raw material sourcing through fabrication, joining and final machining. Re-tooling adds startup costs.

- Knowledge Gaps – Best practices continue evolving as researchers interpret interactions between nano to macro-scale properties and manufacturing processes. Ongoing education from material suppliers smoothes adoption by end product makers.

- Cost Barriers – High R&D expenses for custom materials initially limit orders to low-volume aerospace and elite sports sectors. Scaling production can make costs competitive with conventional materials.

- Health & Safety Unknowns – Little data exists on long-term ecological impacts and human exposure risks for newer materials. Responsible development prioritizes safety alongside performance.

Conclusion

High-tech materials promise to push performance boundaries across multiple industries in coming decades. But fully leveraging their advantages depends on resolving production and commercialization challenges through coordinated efforts linking suppliers, manufacturers and government oversight.

With sound ethics and policies guiding sustainable high-tech material usage, societies worldwide stand to benefit from the next wave of scientific materials innovation. Wider adoption will spark fresh innovations as creative minds outside advanced labs envision new applications for the unique properties of emerging materials.