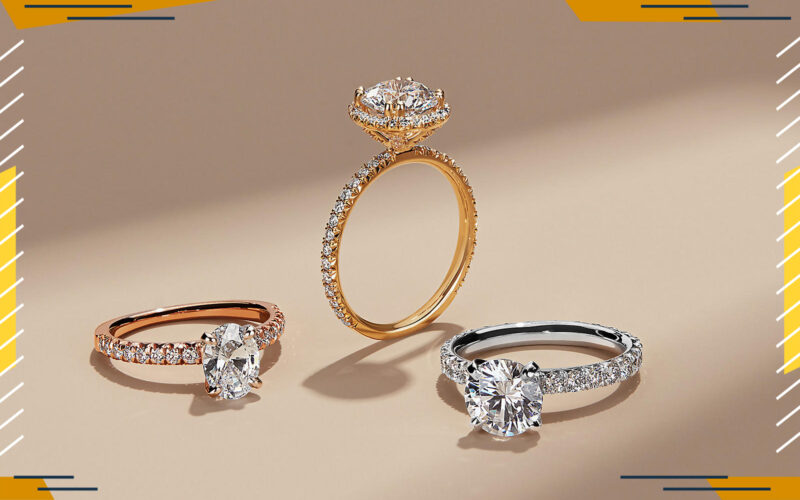

The engagement ring industry is rapidly adapting to the changing times, with 3D printing and customization becoming a popular option for couples seeking unique and special rings. This new technology has allowed jewelers to create intricate designs that were previously impossible using traditional methods of manufacturing.

With 3D printing, customers have more control over the shape, size, style, and design of their engagement rings than ever before. The result? A truly personalized piece is of jewelry that’s as unique as your relationship!

1. Unlocking the Potential of 3D Printing in Engagement Rings

The engagement ring industry is quickly adapting to the rise of 3D printing technology, revolutionizing how couples can customize their rings. With 3D printing, couples have access to a variety of shapes and styles that were previously impossible or too expensive for them to create with traditional methods.

The engagement ring industry is quickly adapting to the rise of 3D printing technology, revolutionizing how couples can customize their rings. With 3D printing, couples have access to a variety of shapes and styles that were previously impossible or too expensive for them to create with traditional methods.

By utilizing this modern technology, customers are able to design anything from classic solitaire diamond rings all the way up to elaborate custom designs featuring multiple stones.

In addition, 3D printers make it possible for jewelers to produce higher-quality jewelry at a fraction of the cost than what could be achieved otherwise. This means that customers now have more options and greater flexibility when choosing a ring for their special day without breaking the bank in the process.

2. Customizing the Perfect Ring with 3D Printing Technology

3D printing technology has revolutionized the engagement ring industry by allowing customers to customize their perfect ring.

Utilizing 3D design software, customers can create a unique design that is tailored to their individual tastes and desires. With this technology, jewelers are able to produce high-quality rings with intricate details and complex geometries more quickly than ever before.

Furthermore, 3D-printed rings have the added benefit of being much more affordable than traditional diamond rings due to fewer labor costs associated with producing them. By using 3D printing, couples can now create one-of-a-kind rings that reflect their own personalities and styles while staying within budget.

3. Crafting Unique and Memorable Engagement Rings Using 3D Printing

The engagement ring industry is being revolutionized by the use of 3D printing technology. With the ability to customize rings and create unique designs, couples are now able to express their individual styles in a way never before possible. 3D printing makes it easier for jewelers to craft intricate and complex designs that can be tailored perfectly for each couple.

Furthermore, this technology eliminates many of the traditional steps involved in jewelry making such as casting or hand carving, allowing rings to be crafted faster with greater precision and detail than ever before. As a result, couples are able to select from an array of personalized options that make their special day even more meaningful.

By leveraging 3D printing technologies, jewelers, such as Engagement rings manchester, have made crafting engagement rings both more creative and cost-effective – creating memorable moments without breaking the bank!

Conclusion

The conclusion of this article is that 3D printing and customization in the engagement ring industry is a booming business. With new technologies, consumers have more options when it comes to designing their own unique rings. The ability for customers to customize their rings has made them more popular than ever before, as couples can now create something truly special together.

Furthermore, 3D printing technology offers a greater level of precision and accuracy than traditional methods, allowing jewelers to produce superior quality products with reduced costs. This will likely lead to increased competition within the industry over time – which ultimately benefits both customers and businesses alike!